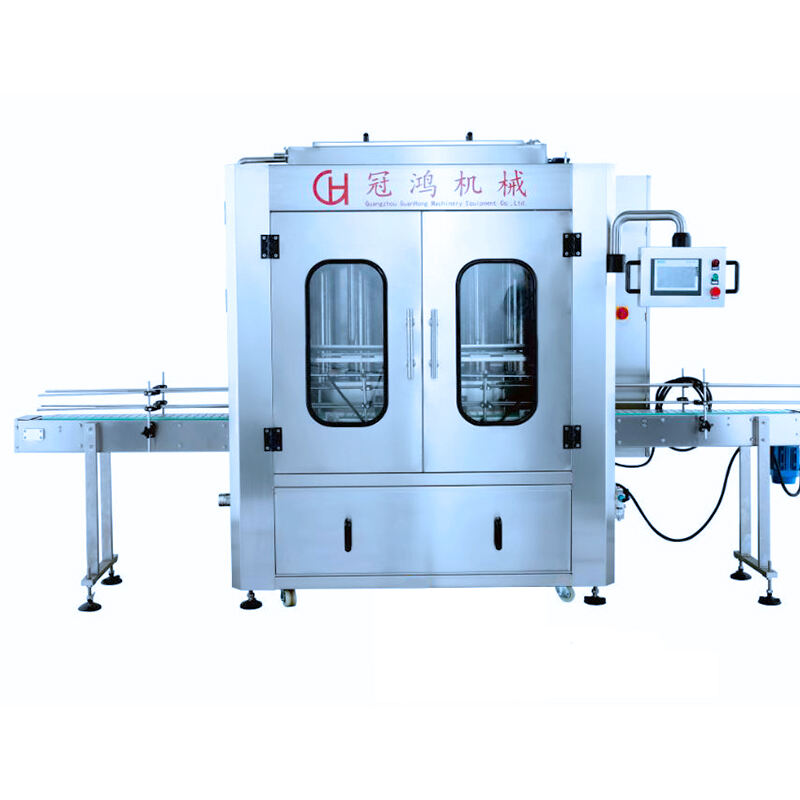

china sealing machine packing

The China sealing machine packing is a state-of-the-art technology designed to secure and protect products through efficient and reliable sealing processes. Main functions include continuous sealing, batch sealing, and heat sealing for various types of packaging such as bags, bottles, and containers. Technological features include an advanced temperature control system ensuring precision in heat application, a user-friendly touch screen interface for easy operation, and compatibility with various types of packaging materials. This machine is widely used in industries such as food and beverage, pharmaceuticals, cosmetics, and electronics, where product integrity and shelf life are paramount.