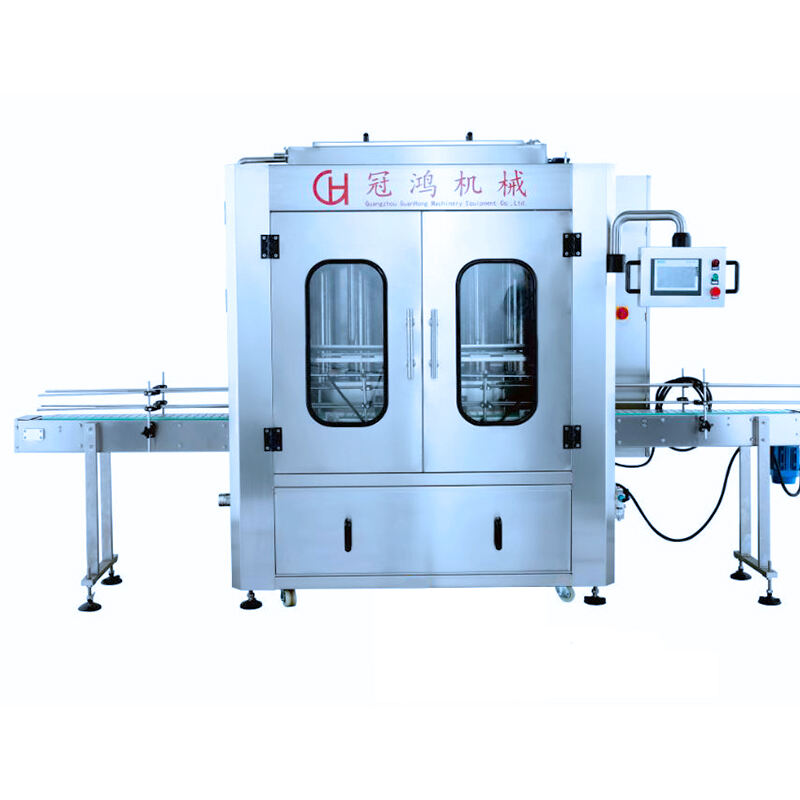

fully automatic bottle filling machines

The fully automatic bottle filling machines represent the pinnacle of efficiency in liquid packaging. These machines are designed to handle the entire filling process without human intervention, from the initial stage of bottle placement to the final sealing and packaging. The main functions include bottle cleaning, filling, capping, and labeling. Technological features such as precise dosing systems, programmable logic controllers (PLC), and human-machine interface (HMI) touch screens ensure high precision and ease of operation. These machines are ideal for industries such as beverages, pharmaceuticals, cosmetics, and food products, where high production rates and stringent hygiene standards are essential.