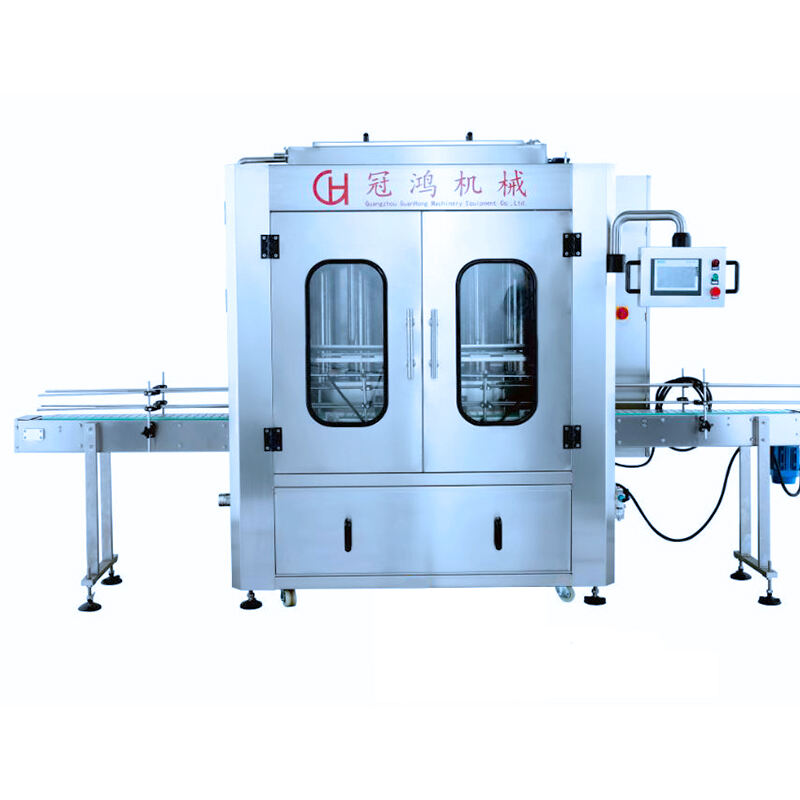

auto liquid filling machine

The auto liquid filling machine is a sophisticated piece of equipment designed to streamline the packaging process for liquids. This machine performs its main functions, which include filling, sealing, and capping, with precision and speed. Its technological features are impressive, boasting programmable logic controllers (PLCs) for intelligent operation, a user-friendly touchscreen interface, and high-precision filling nozzles that ensure accuracy. With its advanced capabilities, this machine is suitable for a variety of industries, including pharmaceuticals, cosmetics, food and beverage, and more. It handles different types of liquids, from thin and foamy to thick and viscous, making it a versatile solution for various liquid packaging needs.