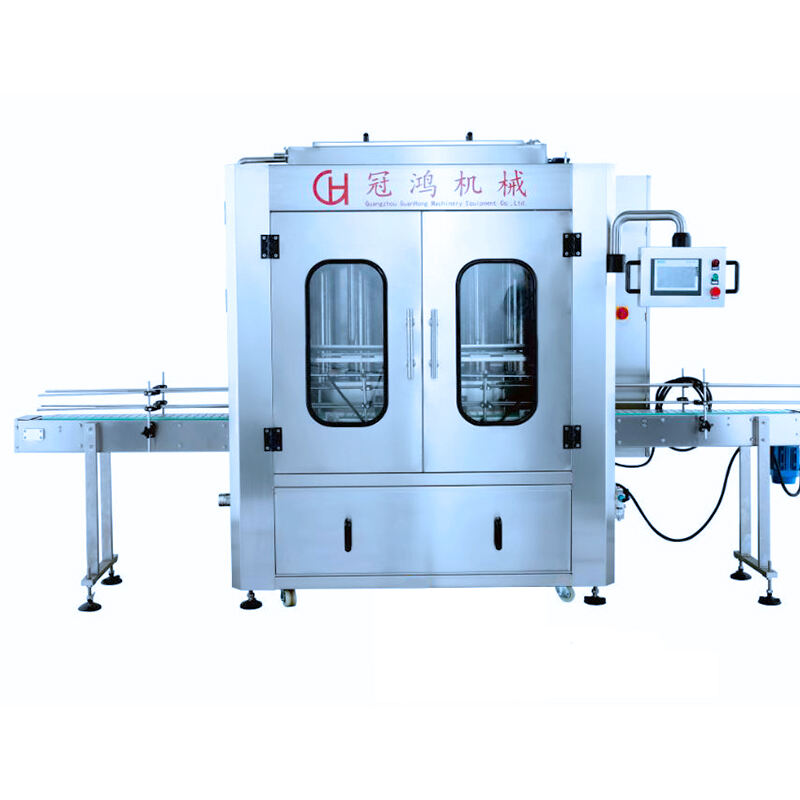

juice filling equipment

Juice filling equipment is a sophisticated system designed to efficiently fill bottles with liquid products, particularly fruit juices. The main functions of this equipment include precise liquid dosing, filling, sealing, and labeling, ensuring a smooth and automated production process. Technological features such as programmable logic controllers (PLCs), touch-screen interfaces, and advanced sensors facilitate ease of operation and high precision. These machines are equipped with sterile filling nozzles and are capable of operating in a variety of environments, making them suitable for the food and beverage industry. Juice filling equipment is versatile and used in applications ranging from small-scale operations to large-scale production facilities, handling everything from purees to high-viscosity nectars.