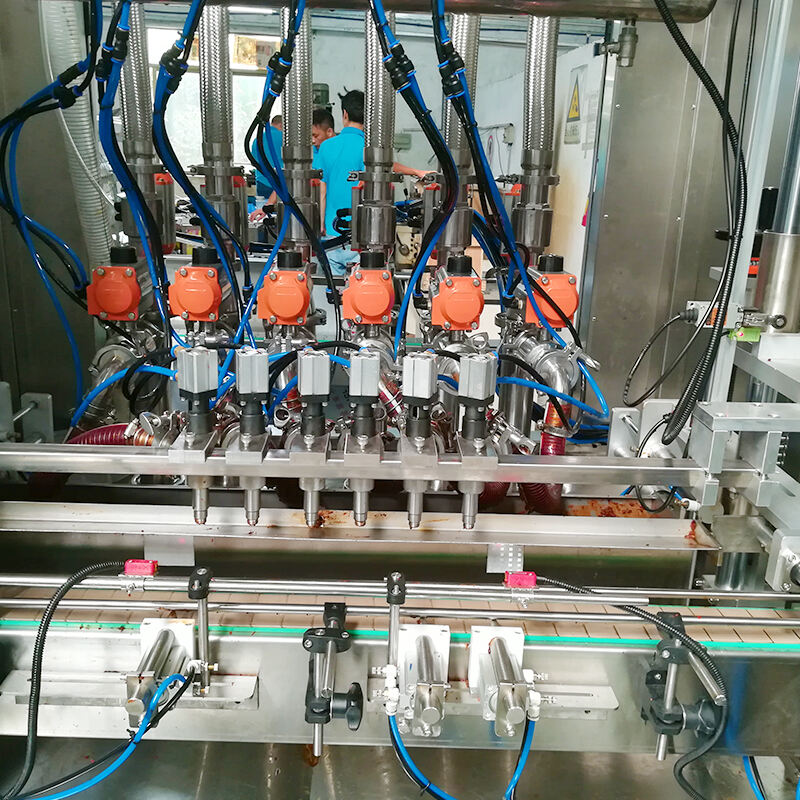

auto bottle filling machine

The auto bottle filling machine is a sophisticated piece of equipment designed to streamline the packaging process for liquids. Its main functions include automatically filling bottles with precise volumes of liquid, sealing them, and then either capping or labeling them as required. Technological features of this machine include programmable logic controllers (PLCs) for easy operation and customization, touch screen interfaces for user-friendly control, and advanced sensors that ensure accurate filling and consistent production. Applications of the auto bottle filling machine span various industries, including food and beverage, pharmaceuticals, cosmetics, and more, making it an indispensable tool for manufacturers looking to enhance productivity and efficiency.