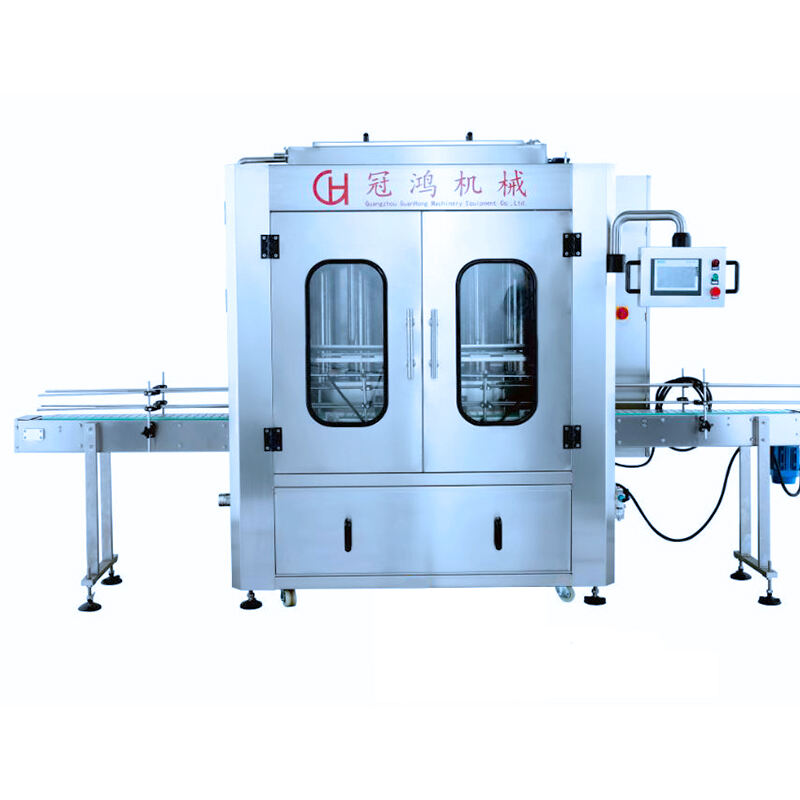

liquid filling machine

The liquid filling machine is a sophisticated piece of equipment designed to fill containers with liquids in a precise and efficient manner. Its main functions include accurate volume measurement, container handling, and sealing. Technological features such as programmable logic controllers (PLCs), touch-screen interfaces, and high-resolution sensors ensure that the machine operates with optimal precision and minimal human intervention. Applications of the liquid filling machine span across various industries, including pharmaceuticals, food and beverage, cosmetics, and chemical manufacturing. It caters to a wide range of liquid products, from lotions and shampoos to beverages and detergents, providing versatile solutions for different packaging needs.