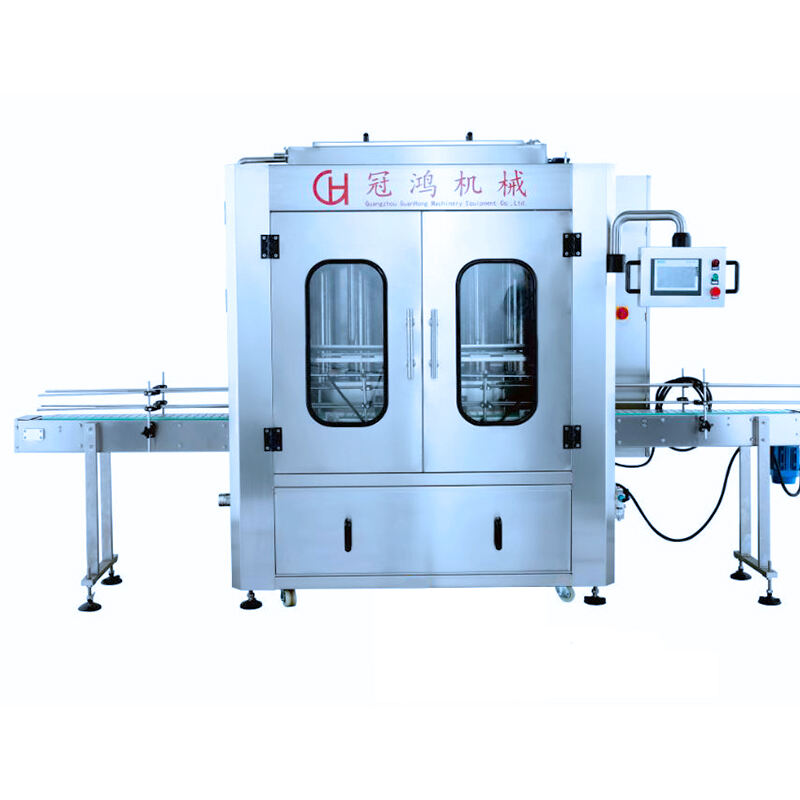

servo filling machine

The servo filling machine is a state-of-the-art solution designed to enhance the efficiency and precision of liquid packaging. Its main functions include the accurate measurement and filling of liquids into containers of various sizes, all while maintaining a high-speed operation. Technological features of the servo filling machine include its programmable logic controller (PLC) which allows for precise control and customization of the filling process, a high-resolution encoder for accuracy, and a touch-screen human-machine interface (HMI) that simplifies operation. This machine is ideal for a wide range of applications including pharmaceuticals, food and beverage, cosmetics, and chemical industries where consistency and reliability in filling are crucial.