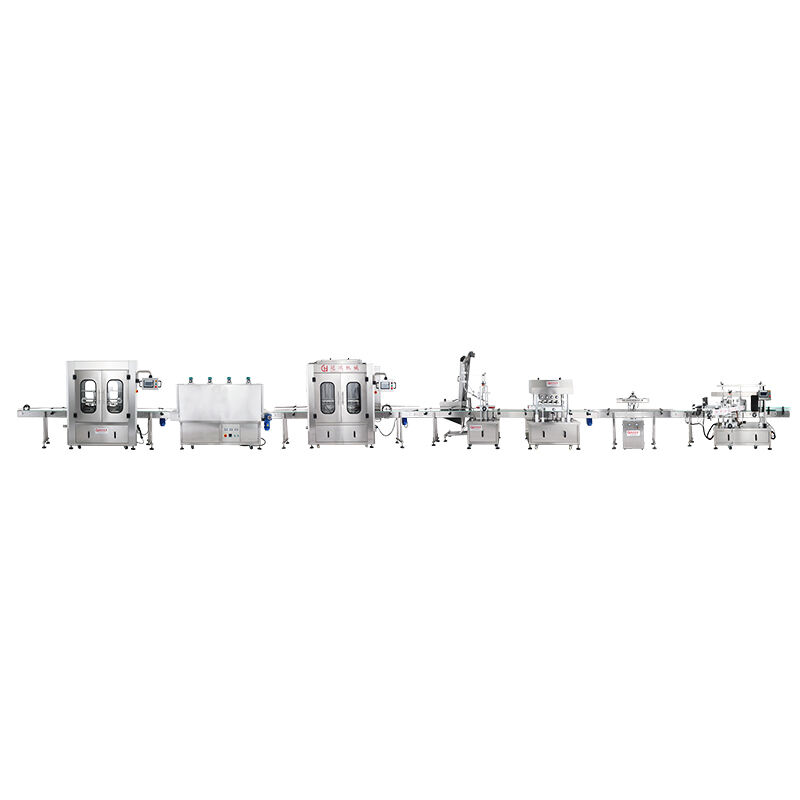

manual paste filling machine

The manual paste filling machine is a versatile piece of equipment designed for the precise and efficient filling of pastes, creams, and other similar products. Its main functions include the accurate measurement and transfer of materials into containers such as bottles, jars, and tubes. Technological features of this machine often include a manually operated lever system that controls the flow of product, adjustable volume settings for different filling requirements, and a no-drip design that minimizes waste and ensures a clean working environment. Applications of the manual paste filling machine span across various industries including pharmaceuticals, cosmetics, food processing, and more, where it is valued for its reliability and simplicity.