liquid filling machine manufacturer

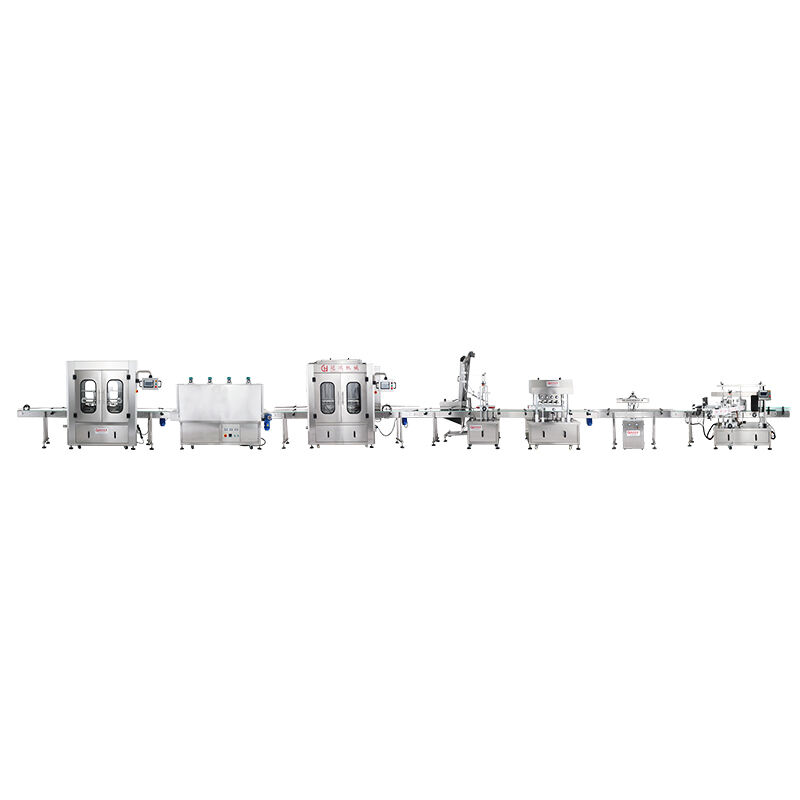

At the forefront of liquid packaging solutions stands our liquid filling machine manufacturer, renowned for creating innovative equipment that streamlines the packaging process. The main functions of our liquid filling machines encompass precise volume measurement, efficient filling, and secure sealing, all of which are vital for maintaining product integrity. Technological features include programmable logic controllers for versatile operation, advanced sensor systems for accurate fill levels, and a hygienic design that meets stringent food and pharmaceutical industry standards. These machines are adept at handling a wide range of applications, from beverages and cosmetics to pharmaceuticals and household chemicals, making them an indispensable asset to manufacturers across various industries.