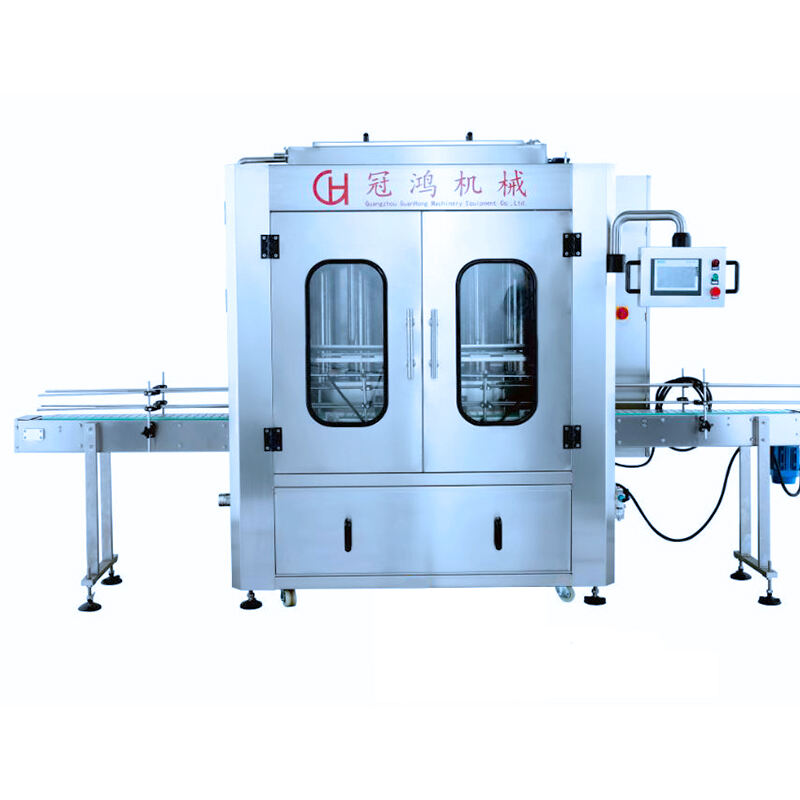

china automatic capping machine

The China automatic capping machine represents the cutting-edge of bottling line technology, designed to enhance productivity and efficiency in a variety of industries. Its main functions include securely applying caps to bottles of various sizes and shapes with precision and speed. Technological features such as a programmable logic controller (PLC) ensure seamless operation and easy integration into existing production lines. This machine employs advanced capping methods that guarantee a tight seal, preventing leaks and tampering. Moreover, it is versatile for different types of caps including screw caps, press-on caps, and aluminum foils. Applications span across pharmaceuticals, food and beverage, cosmetics, and chemical industries, making it an indispensable tool for manufacturers aiming for high-output and consistent quality.