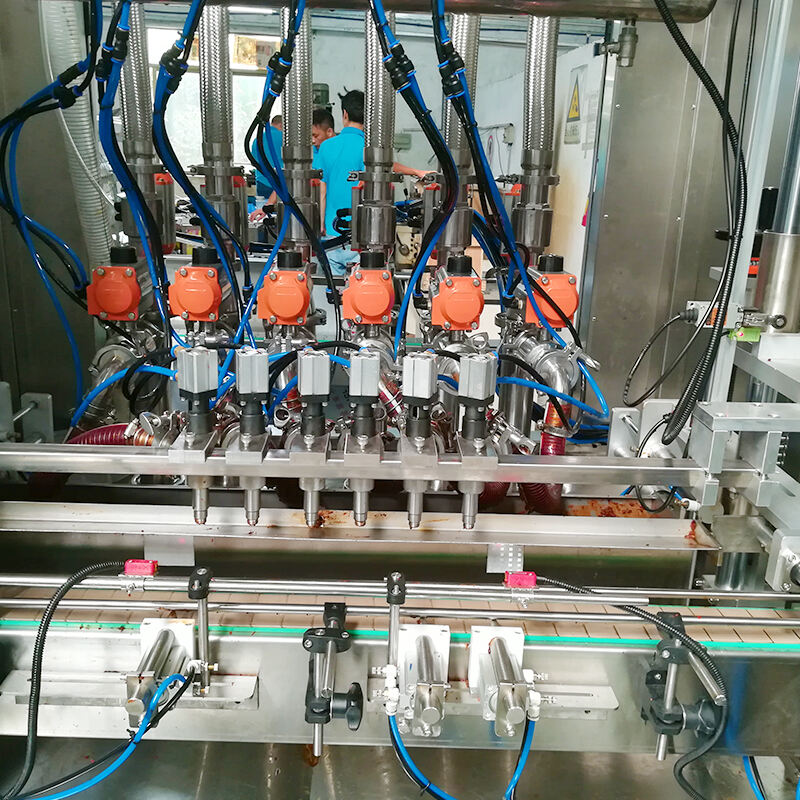

china bottle cap sealing machine

The China bottle cap sealing machine is a state-of-the-art piece of equipment designed for high-efficiency packaging operations. Its main functions include securely sealing bottle caps onto various types of containers, ensuring product integrity and prolonged shelf life. Technological features of this machine include an advanced servo motor control system for precise and consistent capping pressure, an intelligent temperature control system for perfect sealing, and a user-friendly touch screen interface for easy operation and settings adjustment. These machines are versatile, catering to industries such as pharmaceuticals, food and beverage, and cosmetics. With the capability to handle different bottle shapes and sizes, the China bottle cap sealing machine is an indispensable tool for modern production lines.