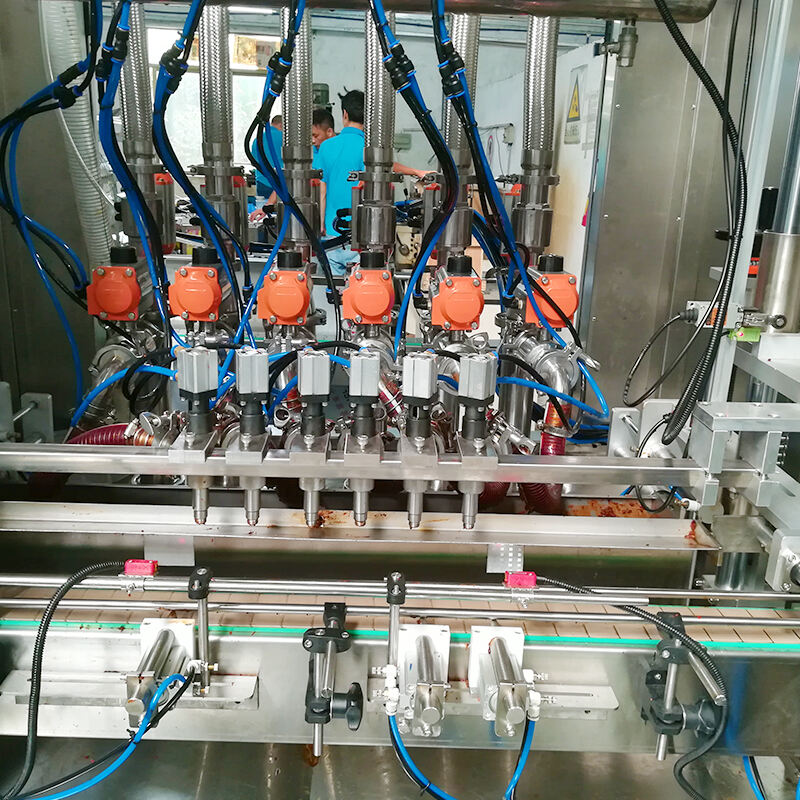

china packing automatic machine

The China packing automatic machine represents a cornerstone of modern packaging technology, designed to streamline and automate the packaging process for a variety of products. This machine's main functions include counting, filling, sealing, and labeling, all of which are performed with high precision and speed. Technological features such as programmable logic controllers (PLCs), touch screen interfaces, and advanced sensors ensure seamless operation and easy integration into existing production lines. It's versatile applications span industries from food and beverage to pharmaceuticals and cosmetics, making it an indispensable tool for manufacturers aiming for efficiency and productivity. With its state-of-the-art design, the machine minimizes human error and maximizes output, catering to the rigorous demands of contemporary production environments.