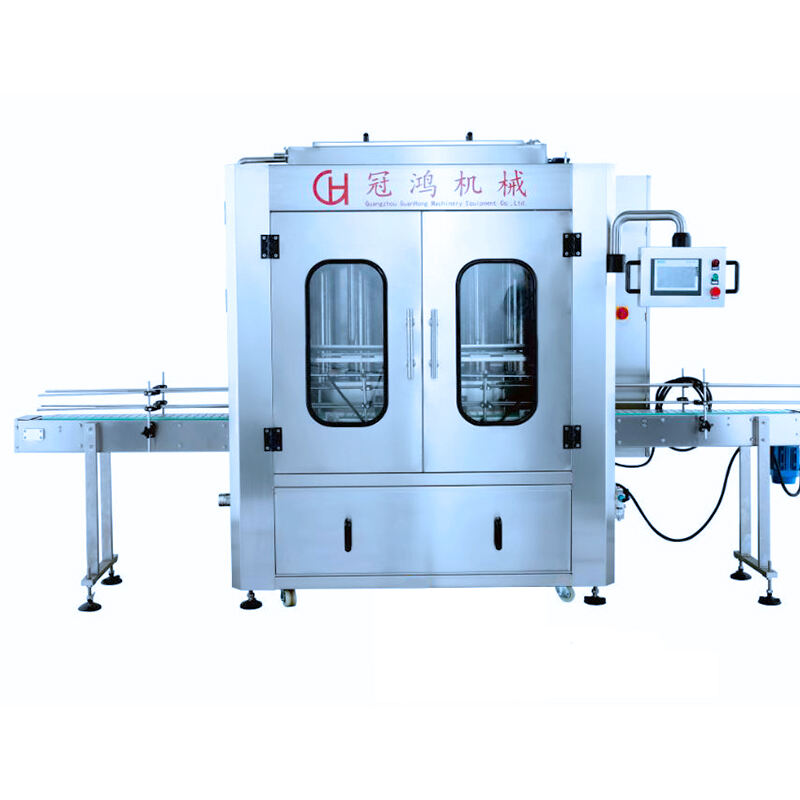

china automated labeling machines

China automated labeling machines are cutting-edge devices designed to streamline packaging processes. These machines offer a range of main functions including label placement, coding, and printing. Technological features of these machines encompass precision sensors, variable speed controls, and advanced software interfaces, ensuring high accuracy and efficiency. Their applications span across various industries such as pharmaceuticals, food and beverage, cosmetics, and manufacturing, where they are used to label bottles, cans, boxes, and other packaging types. The robust construction and user-friendly design of these machines make them an indispensable tool for modern production lines.