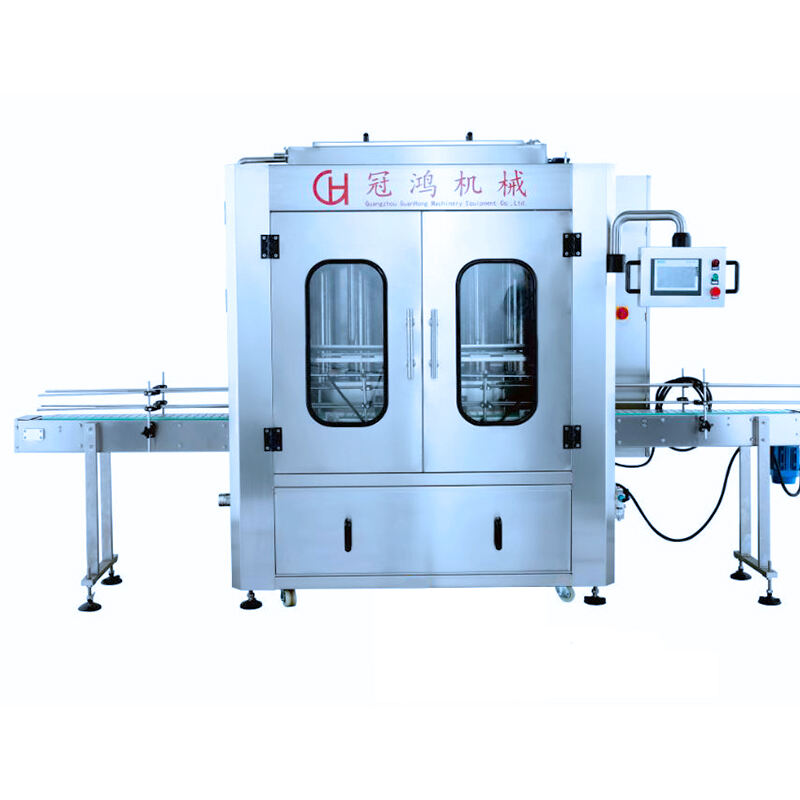

china automated filling machines

China automated filling machines represent the cutting-edge in liquid packaging technology. These sophisticated machines are designed to handle a variety of liquid products, from pharmaceuticals to beverages, with precision and efficiency. The main functions of these machines include filling, capping, and labeling, all performed in a fully automated process that reduces the need for manual labor. Technological features such as programmable logic controllers (PLCs), touch screen interfaces, and advanced sensors ensure precise control over the filling process, resulting in consistent product quality. Their applications span across industries such as food and beverage, pharmaceuticals, cosmetics, and more, making them versatile solutions for modern production lines.