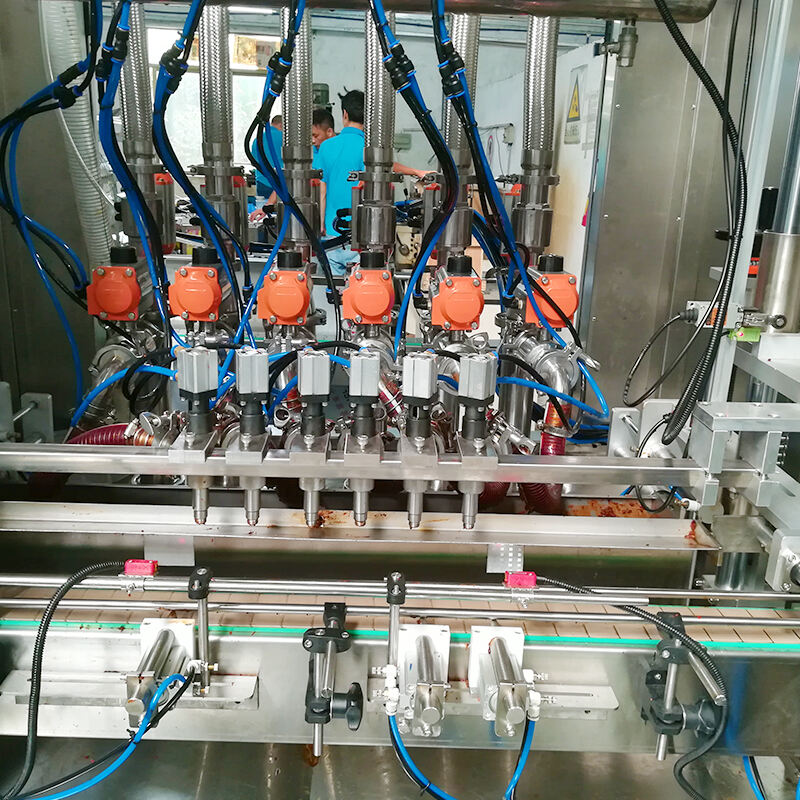

china automatic filling machine

The China automatic filling machine is a cutting-edge solution designed to streamline the packaging process for a variety of products. This machine's main functions include precise filling, sealing, and labeling, ensuring products are packaged efficiently and hygienically. Technological features such as programmable logic controllers (PLCs), touch screen interfaces, and advanced sensors enable seamless operation and easy adjustments to meet different production needs. Applications of the China automatic filling machine span various industries, including food and beverage, pharmaceuticals, cosmetics, and chemicals, making it a versatile and indispensable tool for modern manufacturing.