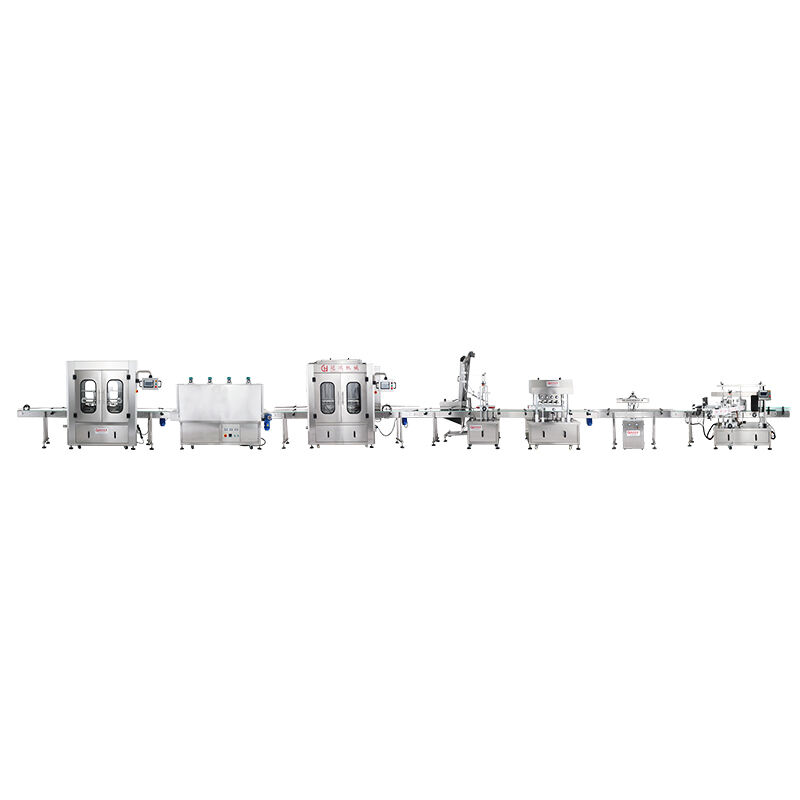

volumetric filling machine

The volumetric filling machine is a sophisticated piece of equipment designed for precise and efficient liquid filling. Its main function is to measure and dispense a predetermined volume of liquid into containers, ensuring consistency and accuracy with each fill. Technological features include a state-of-the-art control system that allows for easy adjustment of fill volumes and the ability to store multiple recipes for different products. The machine is equipped with nozzles that prevent dripping and ensure a clean pour every time. Applications of the volumetric filling machine span across industries such as pharmaceuticals, food and beverage, cosmetics, and chemicals, where the accurate dosing of liquids is crucial. With its high-speed operation and reliability, this machine is an indispensable tool for manufacturers aiming for efficiency and product integrity.