liquid bottling

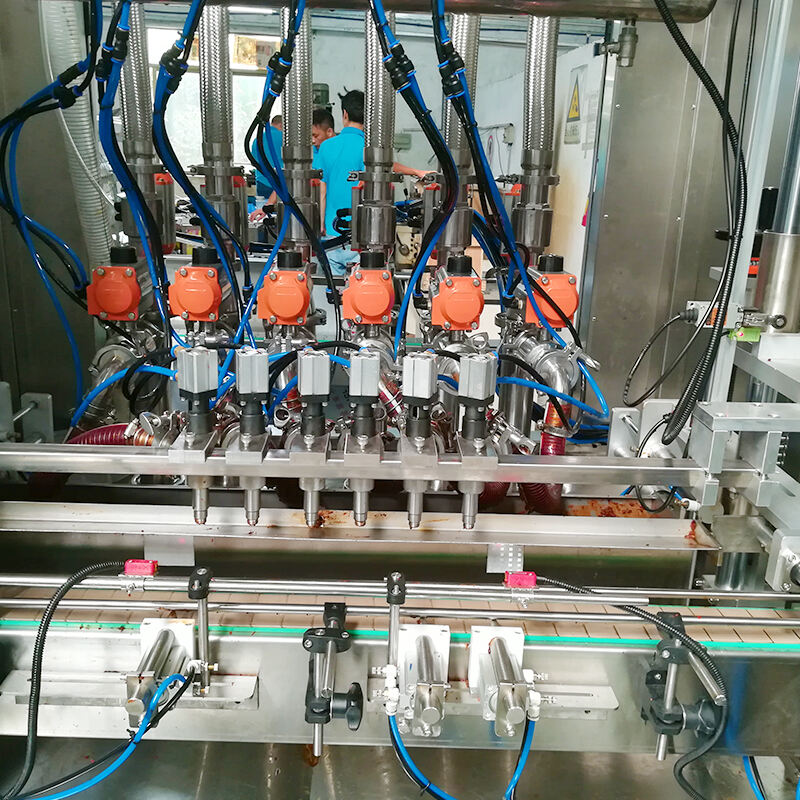

Liquid bottling is a sophisticated process that ensures the safe and efficient transfer of liquids into containers for storage, distribution, and consumption. The main functions of a liquid bottling line include filling, capping, labeling, and packaging. Technological features of modern bottling systems often include automated conveyors, precise liquid filling machines, advanced sterilization units, and computerized control systems to maintain product integrity and consistency. These systems are versatile, capable of handling various liquid products, from beverages to pharmaceuticals. Applications span across industries, from food and beverage to cosmetics and pharmaceuticals, making liquid bottling an indispensable part of modern production lines.